Cheap is not always economical – Quality knives instead of expensive, cheap knives

Whether you are looking for hollow knives, cutting crowns, flat

knives or reversible knives – the market for shredder rotor knives

offers an abundance of cheap knives. These knives are often made

from economical materials less suited for cutting tools, such as

CK45, for example, which is only surface hardened. The service life

of these knives is extremely short and their cost-effectiveness

therefore very poor in the majority of cases.

PR-Technik GmbH, Germany, specialises in developing,

manufacturing and selling industrial knife systems, relying entirely

on premium quality: the hollow knives or cutting crowns in the PR-Technik

range are provided with a 1.5 mm thick, hardened surface, a moderately

hard transition zone and a soft core. They are manufactured from

high-quality steel, specially suited to case hardening, and achieve

optimal hardness by repeated tempering. The high-quality of PR-Technik

knives comes into its own with regard to applications in which the

knives are exposed to impurity-related, sudden forces and loads,

in particular.

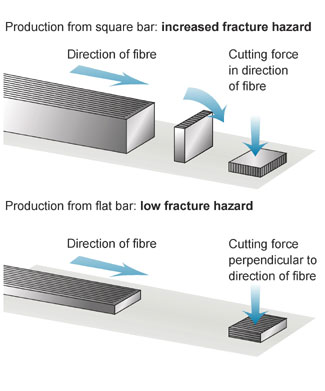

The differences compared to cheap, 1.2379 tool steel knives, can

be even more significant. It is common practice for the majority

of rectangular knives to be produced from a rolled, square steel

section. In terms of material and production costs, this production

method is comparatively economical, but presents a significant disadvantage

as a result of rolling (banding): The forces acting on the knives

during the shredding process act in exactly the same direction as

the fibre (cf. Figure 1). This results in a considerably higher

knife fracture hazard.

PR-Technik GmbH's hollow knives, cutting crowns, flat knives or

reversible knives, in contrast, are always produced from the more

expensive flat steel bar. In these knives the cutting forces act

perpendicular to the fibre with the result that the fracture hazard

is very substantially reduced (cf. Figure 2). In addition, the optimal

heat treatment with multiple tempering processes brings the knives

to the ideal hardness, positively impacting on the cutting force

and the throughput capacity.

Buying cheap knives, then, only has merit at first glance. In economic

terms the investment in expensive, but high-quality, knives is far

more economical, simply because they have much higher service lives

per cutting edge. This results in noticeably lower knife replacement

and time-consuming, expensive machine standstill times are distinctly

minimised.

*******************

More than 20 years experience in shredding technology and intensive

collaboration with machine manufacturers and operators in the timber,

plastics and recycling industries create impetus towards new, innovative

products, opening the way to greater efficiency and profitability.

PR-Technik GmbH develops and produces high-quality industrial knife

systems for customers around the world, in Germany. Our aim is to

provide individual solutions and adaptations for all customer-specific

tasks.

back ->

to the top