News from the PR-Technik Knife Manufactory

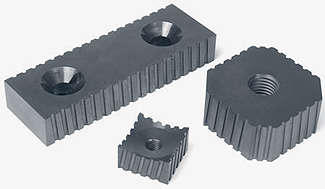

Latest knives developments of PR-TECHNIK:

1. Shell knives with a sharp blade

2. Shell knife with flattened edge

3. Cutting crown 40x40x12 with 4 carbide cutting edges

4. Cutting crown 43x43x19,5 - rear cone

5. Rotor knives 2 cutting edges concave, execution CROSS CUT

6. Rotor knives 2 blades concave, cutting angle 15 °

7. Cutting crown 40x40 with solid carbide plate

8. Cutting crown with extremely concave cutting edge profile

learn more ->

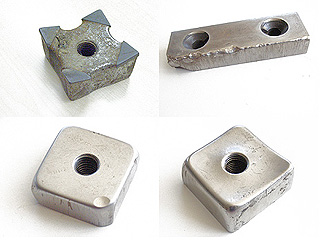

Cheap is not always economical – Quality knives instead of expensive, cheap knives

Whether you are looking for hollow knives, cutting crowns, flat

knives or reversible knives – the market for shredder rotor knives

offers an abundance of cheap knives. These knives are often made

from economical materials less suited for cutting tools, such as

CK45, for example, which is only surface hardened. The service life

of these knives is extremely short and their cost-effectiveness

therefore very poor in the majority of cases.

learn more ->

Knife wear in crushing machines and its negative consequences

In addition to the machine itself, which consists of blades and counter-blades (stator knives) is a cutting system existing crusher, the most important component for an efficient crushing process. Therefore it is necessary, based on the material to be shredded to make the right Cutter selection with respect to material hardness and cutting edge geometry.

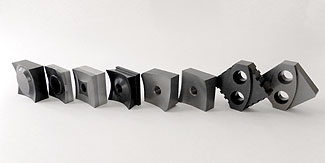

New blade system CROSS - CUT

This worldwide patented blade system with its unique cutting

geometry opens totally new perspectives in the shredding technology

sector. The cutting intermittent has the shape of a saw tooth. This

produces an aggressive cutting behaviour with shredding of plastics,

wood, paper, paper board, metal, and waste. Consequently, the advantages

and benefits for you are as follows:

- a lower power and energy requirement

- bearing preserving and more quiet running of the rotor

- a higher material throughput

- more homogeneous shreddered material

- a lower percentage of fine dust in the output-material

- an optimal lifetime behaviour